TOTAL PRODUCTIVE MAINTENANCE

JIPM TPM AWARD

JIPM launched the PM award system in 1964 to strengthen the improvement of enterprise constitutions and contribute to the development of industry, by promoting the modernization of plant maintenance technologies. The TPM Excellence Awards, in which the results of plants” TPM activities are judged & honoured have been awarded to some 2000 plants since the awards inception. These awards play a valuable role in JIPM’s assessment operations for the development of Japan’s Industrial Sector. In India CII TPM club has been authorized by JIPM to conduct stage 1 review on preparedness of company for challenging the award.

Why Challenge the TPM Award?

Do you think of TPM as a tool to reduce breakdown? Think again. Our recent study has proven that TPM can became a strategic weapon for strategies to survive in global competition. Most of the companies using TPM in India were able to reduce manufacturing cost by 35% , improve productivity by 60%, and reduce defect by 80%. If you are a manufacturing organization are these not the top organization, are these not the top strategic agenda you need to work on?

TPM Award Method & Coach

PROVIDENCE Counsellor will conduct initial TPM diagnosis with an aim to prepare for the TPM category A award. Our counsellor shall be facilitating the followings:-

- Review of various initiatives with top management team.

- TPM program for the Sr. management & middle level.

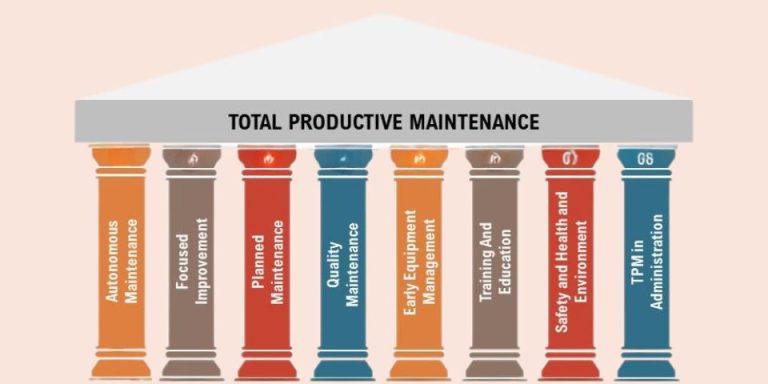

- Starting eight pillar activities & formal “kickoff function for TPM”

- Comprehensive training to TPM champs on various aspects of TPM

- Creation of world class visual workplace by initializing the 5S

- TPM implementation activities (detailed program enclosed)

- Preparation for JIPM, TPM award ( 2 ½ years down the line )Once the company achieves a reasonable level the JUSE consultant will be called for pre application review.

Time frame for achieving category A Award

As per JIPM guidelines a company challenging the award has to practice TPM for minimum three years. Total time for implementation and challenging the Category A award is 3 ½ Years.

Providence Experience

We have a senior team of TPM experts who have successfully implemented this initiative in more than a dozen companies. It has come out as a very strong tool for shop floor as well as overall improvement. Approach is based on Zero down time and loss reduction and can be very useful to the organization who have internal problems on productivity, quality & efficiency. Our clients are Steel Makers, Edible Oil Manufacturer, Roll Manufacturers, Mines, Cement Plants etc.